Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

High-Precision injection molding parts for Industrial, Consumer & Specialized Applications

We deliver precision injection molding services that combine rapid production cycles with exceptional dimensional accuracy. Our state-of-the-art automated systems maintain tolerances within ±0.1mm, making us the ideal partner for complex geometries and demanding applications across industries.

Precision Engineering

Tight tolerances maintained within ±0.1mm

Automated production with precision tooling

Complex geometries: hollow structures, multi-axis curves, embedded inserts

CNC-grade measurement systems for verification

Material Expertise

Engineering thermoplastics: ABS, PC, PA (Nylon), POM, PP, PVC

High-performance polymers: PEEK, PTFE, PPS

Enhanced resistance to corrosion, UV degradation, and chemical exposure

30-50% weight reduction compared to metal alternatives

Surface Treatment Options

Polished finishes and textured surfaces

Anti-static and UV-resistant coatings

Custom aesthetic and functional treatments

Enhanced wear resistance

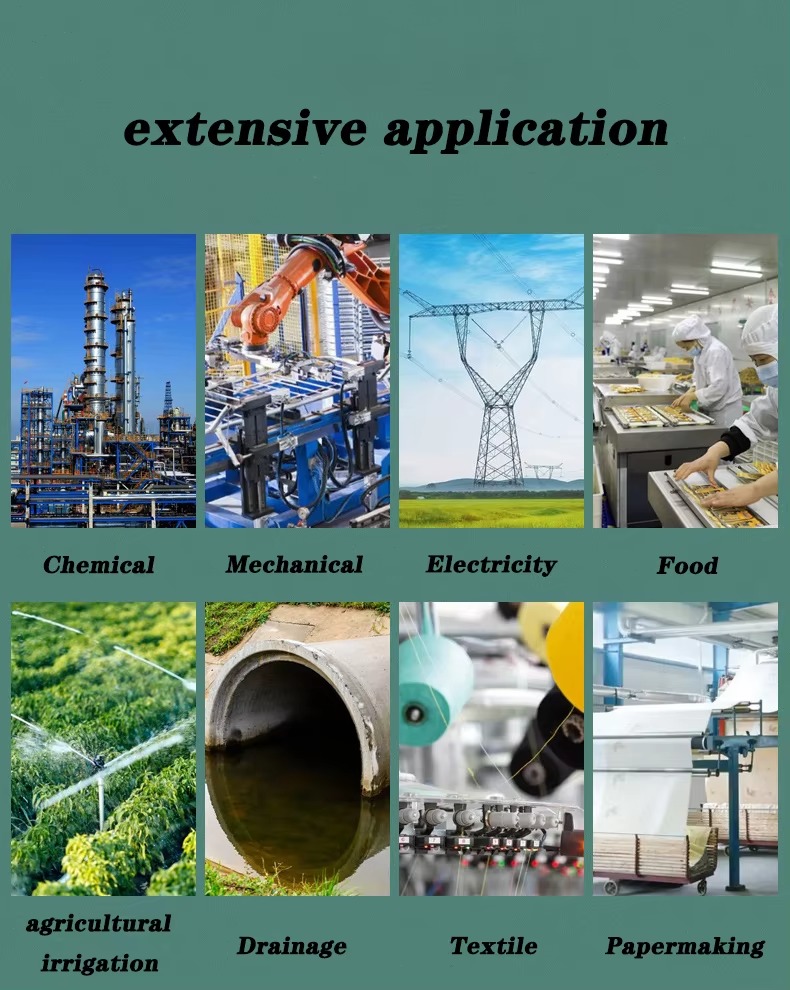

Industrial Applications

Machine guards and safety components

Conveyor system elements

Structural connectors and brackets

Equipment housings and enclosures

Consumer Products

Ergonomic handles and grips

Decorative trims and fittings

Furniture components

Custom packaging solutions

Specialized Sectors

Medical device housings and non-contact instruments

Solar panel mounts and renewable energy components

Wind turbine accessories

Agricultural hardware and equipment

Electronics & Automotive

Electronic enclosures and connectors

Automotive brackets and trim components

Sensor housings and protective covers

Control panel interfaces

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.