Send Message

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

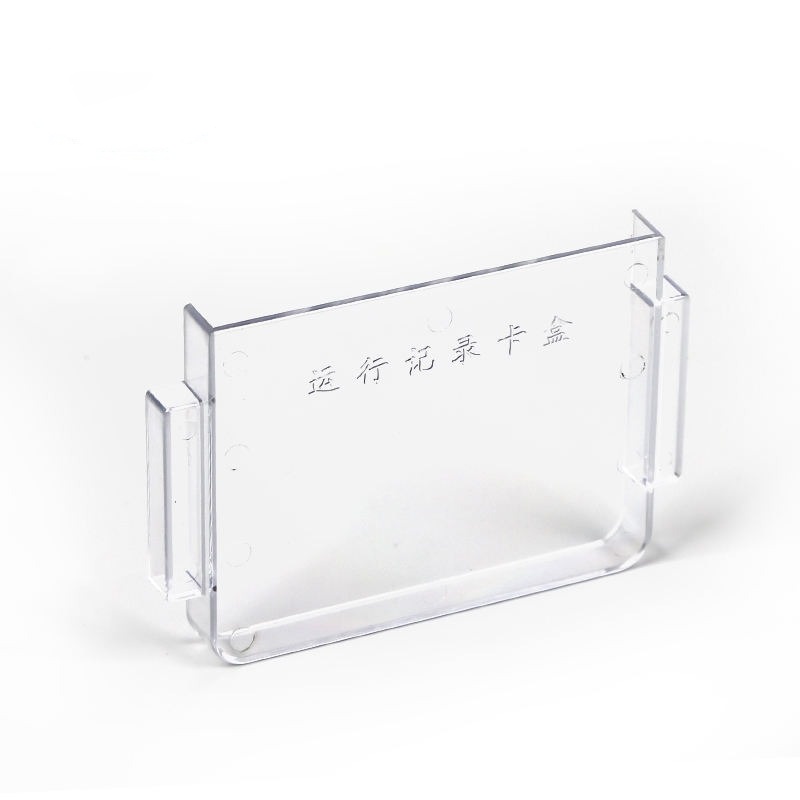

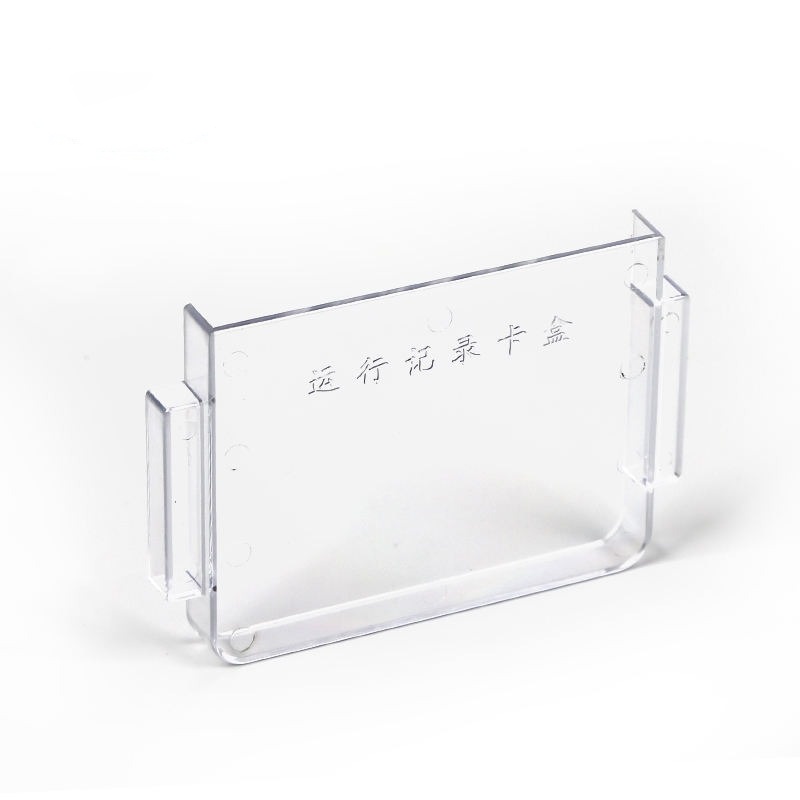

| Precision Engineering & Customization | Utilizing state-of-the-art injection molding, we achieve precise dimensions, complex geometries, and intricate details. This allows for fully customizable features including mounting points, ventilation holes, cable glands, and aesthetic elements like texture and color. |

| Advanced Material Selection | We use high-performance engineering plastics—such as polycarbonate for impact resistance, ABS for a robust balance of strength and cost, and Nylon for chemical and wear resistance—to ensure durability and long-term reliability. |

| Superior Environmental Resistance | These enclosures are designed to withstand challenging conditions, offering excellent protection against impact, chemicals, UV radiation, and moisture, guaranteeing performance both indoors and outdoors. |

| Enhanced Functionality & Integration | The design prioritizes ease of use, with features that facilitate simple assembly, efficient heat management, and straightforward integration into larger systems. |

| Cost-Effective Manufacturing | The injection molding process ensures high consistency and scalability, delivering superior quality at a competitive cost, even for large production runs. |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.