Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

Working with a professional supplier for these components involves a precise process:

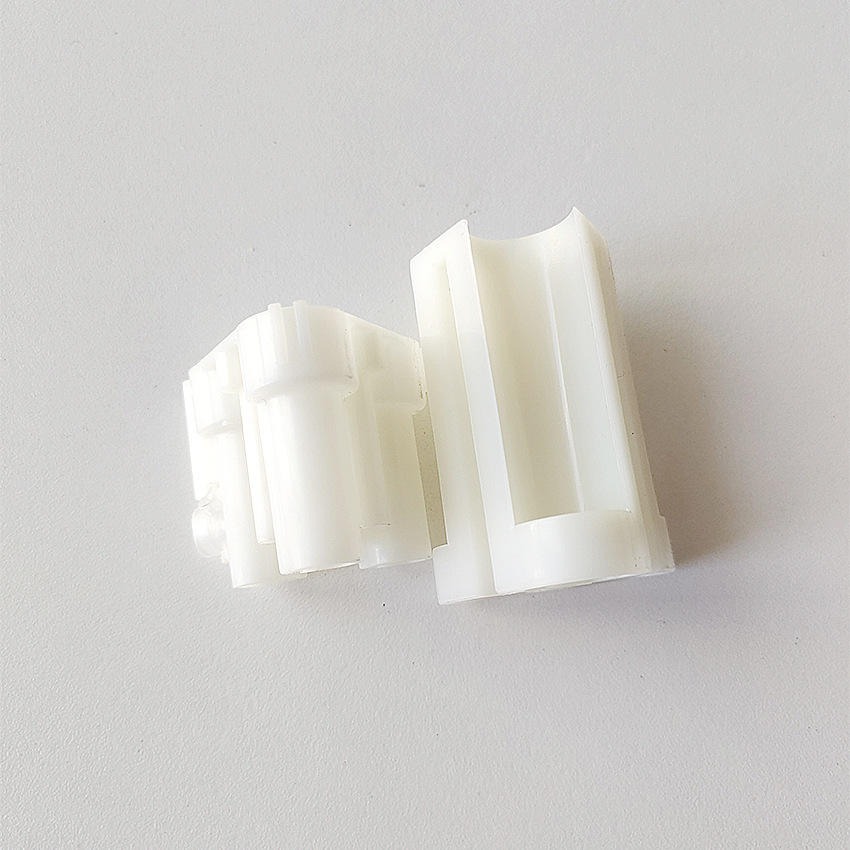

Design & Material Selection: You provide the CAD model. The supplier may recommend a specific grade of Nylon (e.g., Nylon 6, Nylon 66, or Glass-Filled Nylon (PA+GF) for extra strength and rigidity).

Pre-Drying: Nylon is hygroscopic (it absorbs moisture from the air). A professional molder must dry the pellets before molding to prevent defects and loss of strength.

Precision Mold Manufacturing: A high-quality, hardened steel mold is created to withstand the abrasiveness of Nylon and the high volumes typical of these industries.

Injection Molding: The dried Nylon is melted and injected under high pressure into the mold.

Post-Processing: Parts may be deflashed or subjected to conditioning to stabilize their moisture content and final mechanical properties.

| Sector | Typical Nylon Parts | Why Nylon is Used |

| Industrial Use | Gears, bearings, bushings, conveyor components, sensor housings, electrical connectors, machine guards. | Wear Resistance: Lasts longer than metal in some sliding applications. Self-Lubricating: Reduces maintenance. Lightweight & Corrosion Resistance. |

| Household Appliances | Gears in blenders/mixers, tracks for dishwasher racks, pump impellers, motor housings, clips, latches, and connectors in washing machines, dryers, and vacuums. | Durability: Withstands repeated use and stress. Heat Resistance: Handles hot water and motor heat. Electrical Insulation: Safe for motor and electrical components. |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.