Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

Recommended Material:

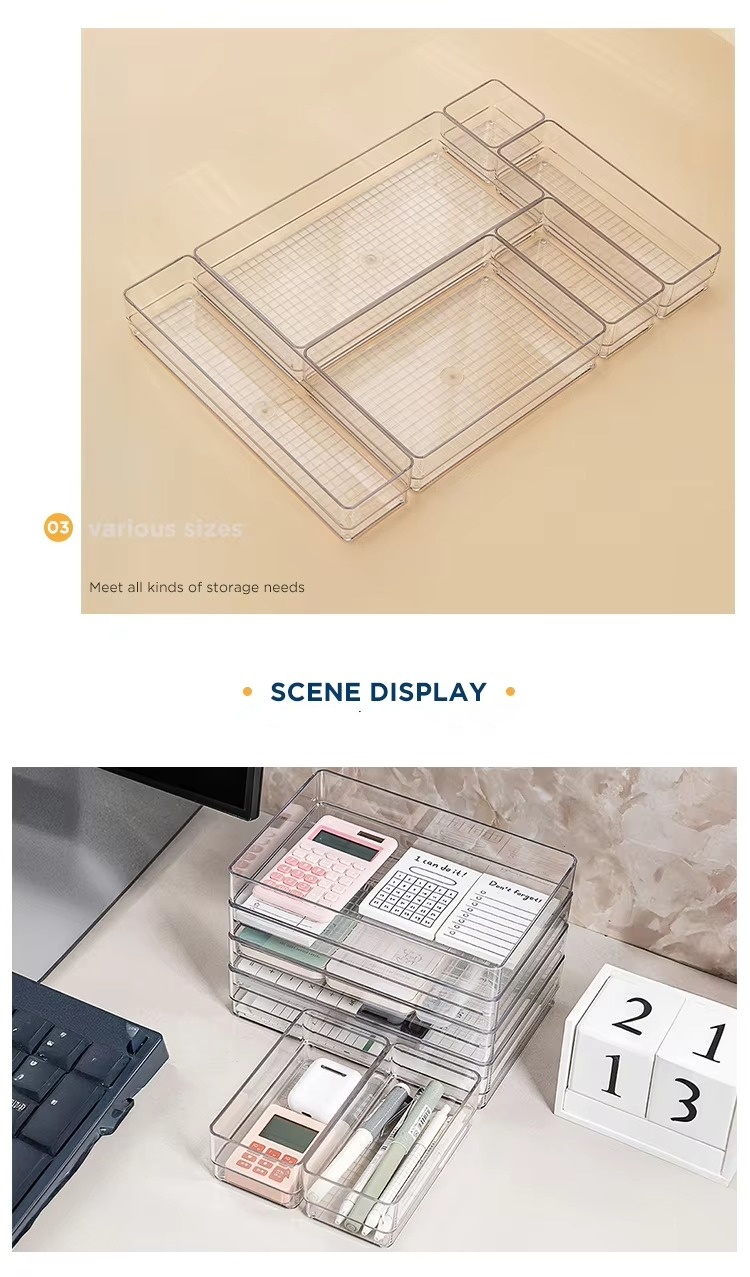

Primary Choice: Polypropylene (PP)

Pros: Excellent chemical resistance, very durable (high fatigue resistance for hinges on lid), good impact strength, and generally lower cost than PET. Can be made in translucent/transparent grades.

Cons: Achieving water-clear transparency is more difficult than with PET; it often has a slight blueish or hazy tint.

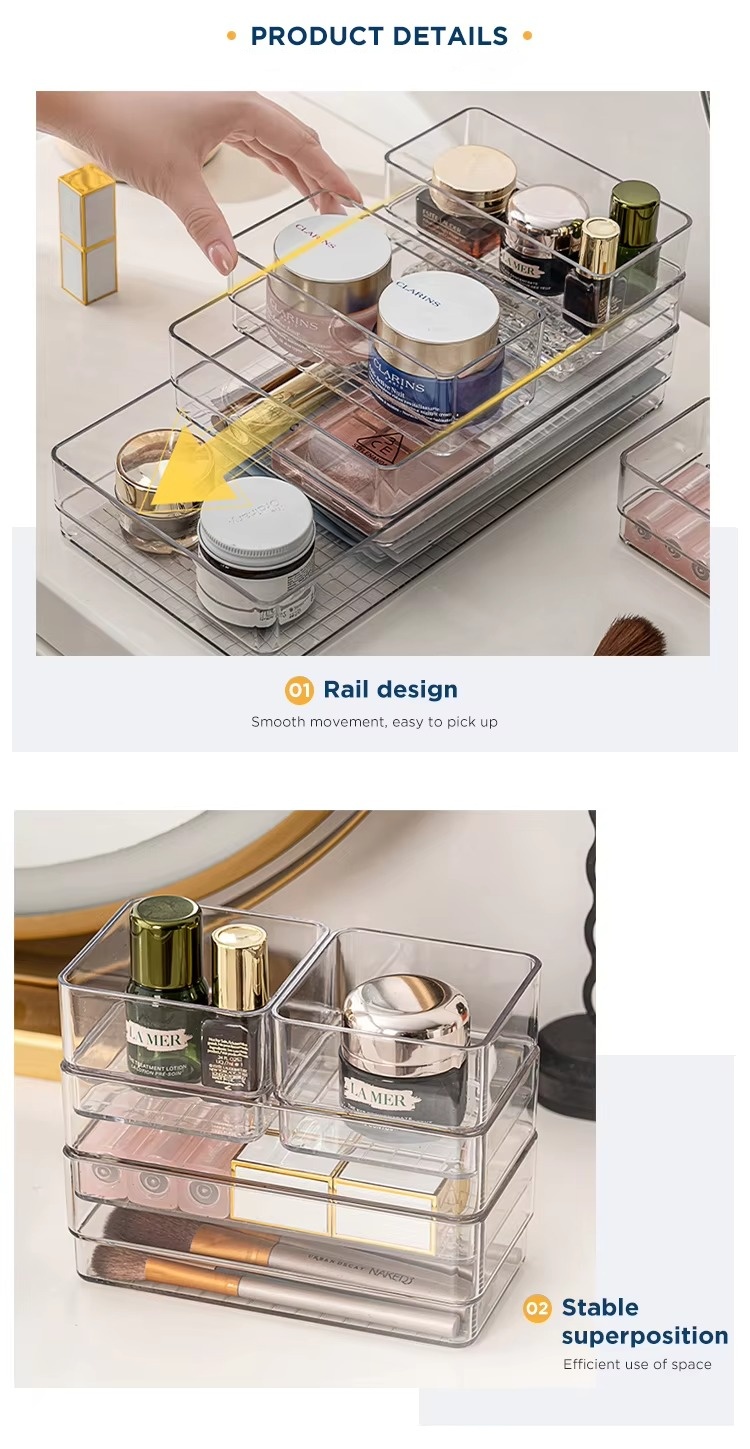

Premium Choice: Polyethylene Terephthalate (PET)

Pros: Superior clarity and gloss, very stiff and strong, excellent barrier properties.

Cons: Can be more brittle (impact-modified grades are available), generally higher cost than PP.

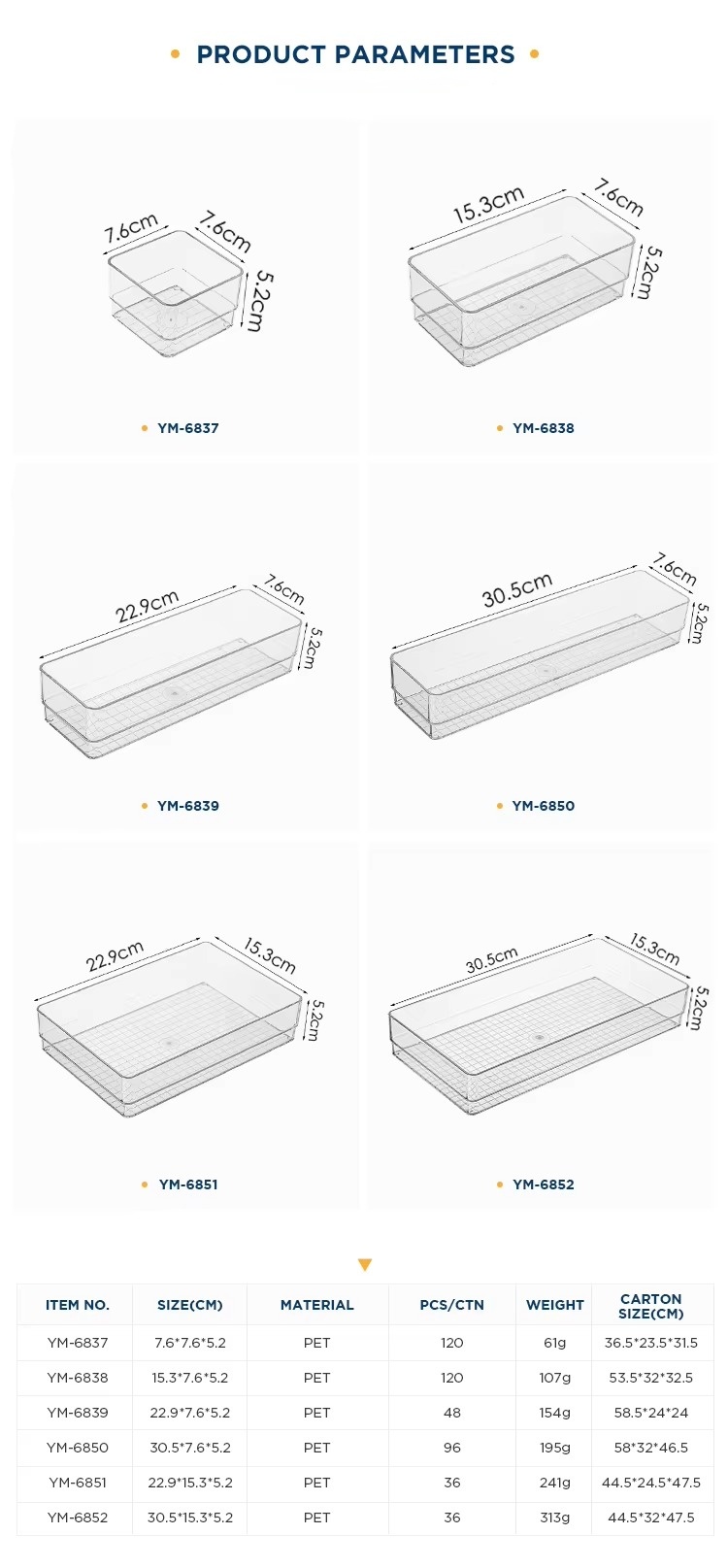

Technical Details:

Wall Thickness: Consistent wall thickness (e.g., 1.5mm - 2.0mm) is critical for injection molding to prevent sink marks and warping.

Draft Angles: A minimum of 1-2 degrees of draft on all vertical walls is essential for de-molding without scratches.

Parting Line: Strategically placed to be unobtrusive and not interfere with the stacking function

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.