Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

Plastic injection mold Custom plastic parts

We deliver high-quality, durable, and cost-effective Industrial plastic parts tailored to your exact specifications. Our expertise spans the entire product lifecycle, from initial concept validation through low-volume batches to full-scale mass production, providing the flexibility and efficiency modern manufacturers need.

Our parts are defined by their superior performance and tailored material properties.

Uncompromising Quality: We guarantee high precision, excellent dimensional stability, and a superior surface finish, even for complex geometries and tight tolerances.

Engineering-Grade Materials: We select from a wide range of polymers—including ABS, Nylon, Polypropylene, and Polycarbonate—based on your needs for heat resistance, chemical resistance, impact strength, and aesthetics.

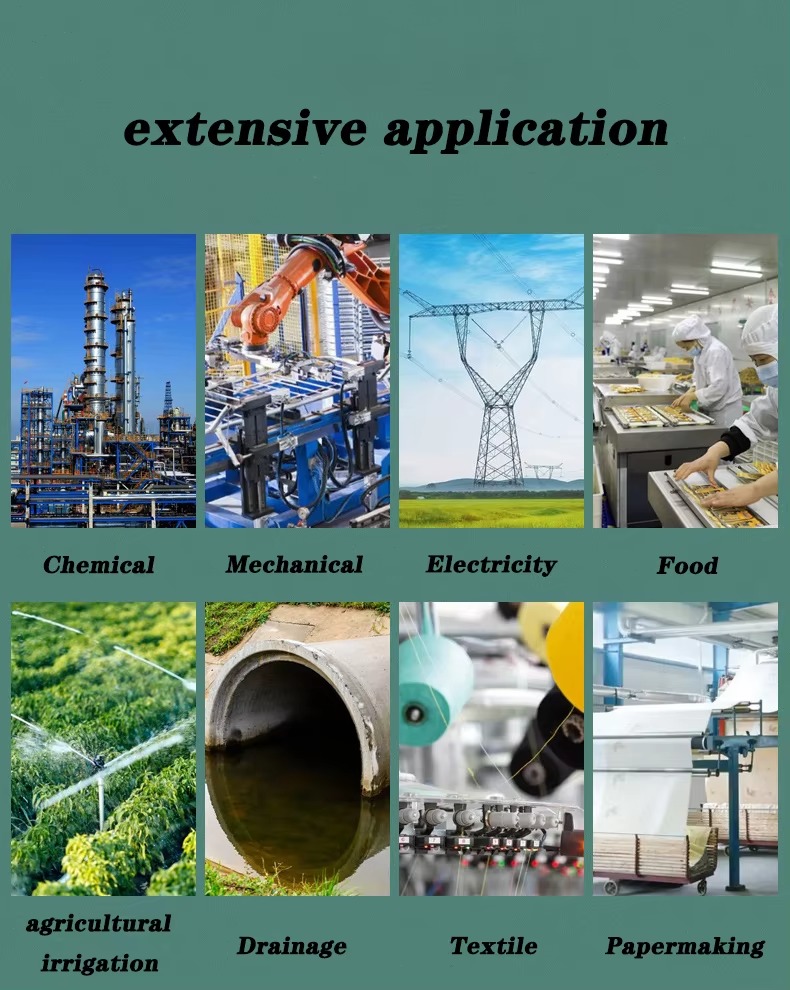

Our components are critical to innovation and reliability across diverse sectors:

Automotive: Interior/exterior trim, dashboards, control modules, and under-the-hood components.

Electronics: Durable housings, connectors, and cases for circuit boards and devices.

Medical: Sterilizable instrument casings, surgical tools, and disposable items requiring biocompatibility.

Consumer Goods: Lightweight, strong, and aesthetically pleasing components that enhance product functionality and user experience.

We provide more than just a box. We deliver a tailored protective solution that combines engineering expertise with manufacturing precision. By leveraging our ODM/OEM capabilities and design flexibility, you can accelerate your time-to-market and ensure your electronic components are housed in a secure, reliable, and professionally finished enclosure.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.