Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

Material Spotlight: Acrylonitrile Butadiene Styrene (ABS)

ABS is a versatile thermoplastic polymer chosen for its excellent mechanical properties:

High Impact Resistance: Withstands physical shock and harsh handling.

Good Heat & Chemical Resistance: Performs reliably in challenging environments.

Rigidity and Strength: Provides structural integrity for protective and supportive components.

Excellent Surface Finish: Yields a visually appealing, ready-to-use part that can be easily painted or plated.

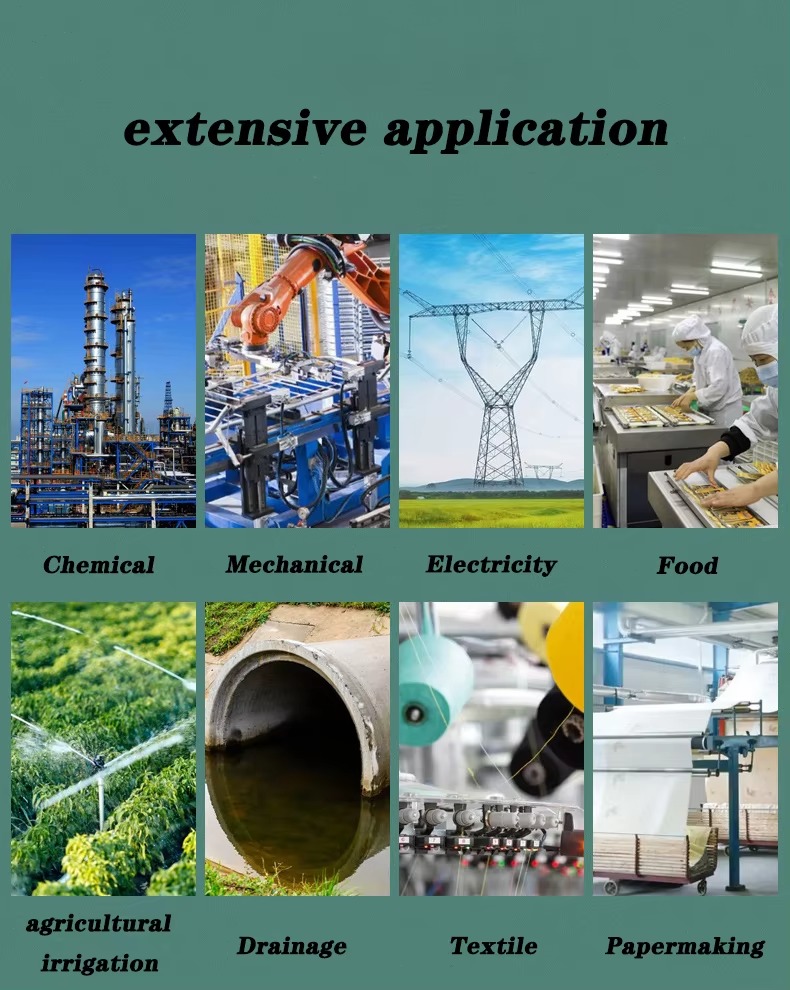

Applications by Industry

Our custom ABS parts are trusted across multiple sectors for critical applications:

Electronics & IT: Durable housings and enclosures for routers, printers, power supplies, and control units.

Automotive: Both interior (dashboards, door panels, control knobs) and under-the-hood components.

Industrial Equipment: Protective casings, machine guards, components for automation systems, and conveyor belt parts.

Consumer Goods: Housings for appliances, tools, and other consumer products requiring a robust plastic shell.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.