Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

Key Features & Benefits

Superior Material Properties: Manufactured from ABS (Acrylonitrile Butadiene Styrene), these parts offer excellent impact resistance, good thermal stability, and high structural strength.

Exceptional Precision: We guarantee high dimensional accuracy and a smooth surface finish, part after part.

Durability in Demanding Environments: Ideal for applications where toughness and long-term reliability are non-negotiable.

Lightweight & Cost-Effective: A robust alternative to metal, reducing weight and overall part cost without sacrificing performance.

Full Customization: Available in custom colors and geometries to seamlessly integrate with your product design and branding.

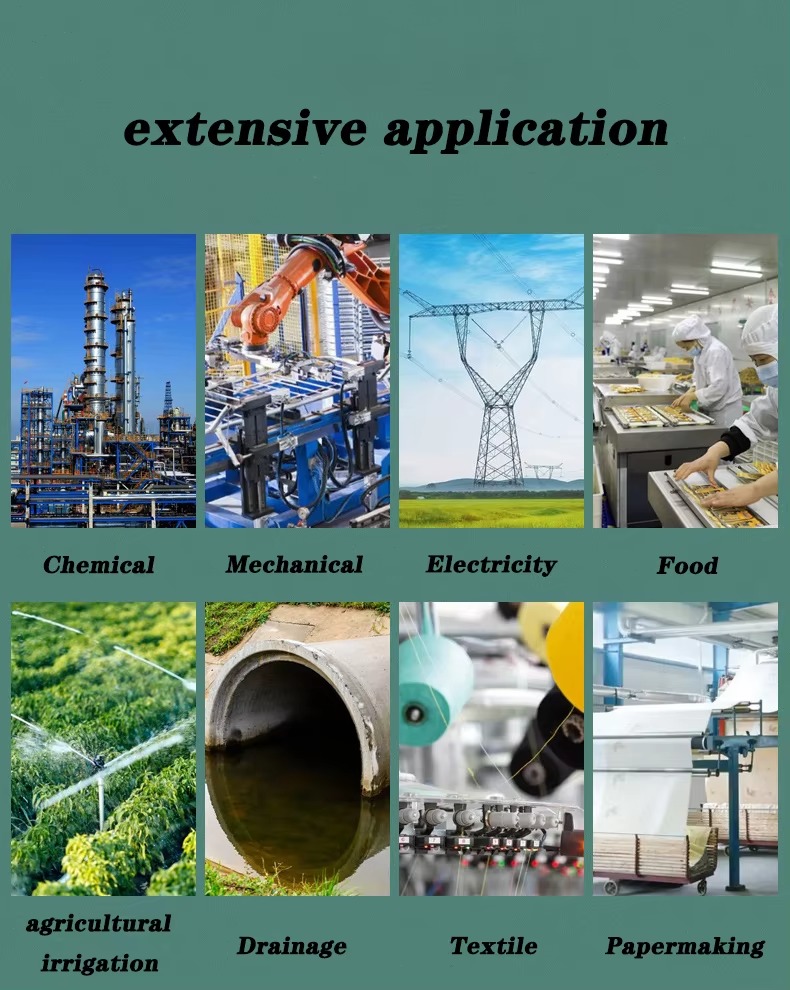

Applications

Automotive: Interior trim, dashboards, connectors, and housings.

Electronics: Durable casings for devices, internal mounts, and buttons.

Consumer Goods: Appliance housings, tool bodies, and toy components.

Medical Devices: Housing for non-implantable medical equipment and instrument handles.

Industrial Equipment: Machine covers, guards, and custom components.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.