Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

| Precision & Consistency | Advanced injection molding techniques ensure every part meets exact dimensional specifications with high repeatability. |

| Durability & Performance | High impact resistance, excellent dimensional stability, and a superior surface finish. |

| Durability & Performance | High impact resistance, excellent dimensional stability, and a superior surface finish. |

| Cost-Effective Production | Efficient mass production reduces per-part cost and minimizes material waste. |

| Design Flexibility | We can produce everything from simple standard shapes to highly complex, custom-designed geometries. |

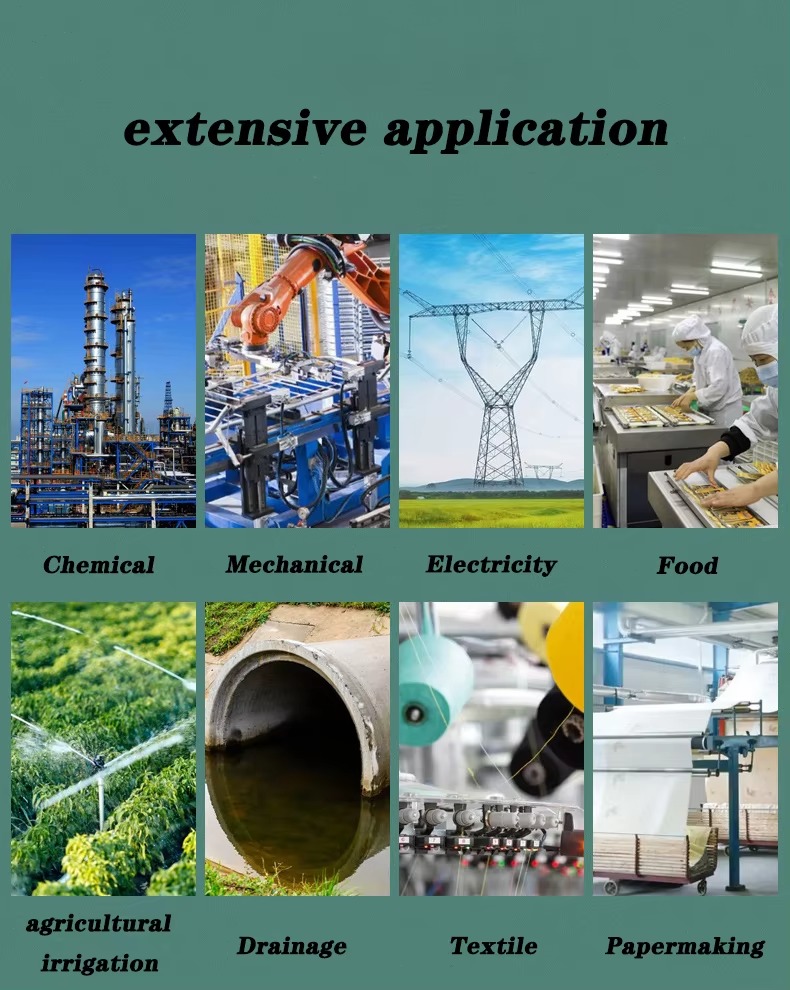

Applications

Our molded parts are trusted across industries, including:

Automotive: Interior trim, connectors, under-hood components.

Medical: Device housings, fluid handling parts, surgical tools.

Consumer Electronics: Durable casings, buttons, and internal mounts.

Industrial Equipment: Covers, gears, housings, and custom components.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.