Medical bone cement is a medical material used in orthopedic surgery. It is injected into the body through a series of matching injection molding kits. During vertebroplasty, bone cement is injected into the vertebral body. This medical technique, used to fill bone gaps or reshape bones, stabilizes the vertebral body. Because some of its physical properties and its appearance and properties after solidification resemble white cement used in construction and decoration, it is named bone cement. Bone cement products include mixing bowls, mixing spoons, funnels, catheters, end caps, bone cement tubes, and cleaning rods. These

Plastic injection molding parts are required. Below, we'll share details about precision medical injection molding processing for medical bone cement kit injection molding manufacturers.

Existing bone cement syringes typically have a cylindrical injection chamber. Mixed bone cement is poured into the chamber, and one end of a plunger is inserted into the chamber, squeezing the cement to achieve injection. The cross-section of the injection cavity is the same, often requiring significant pressure to inject into the body. Due to the inherent viscosity of bone cement, the cross-sectional diameter of the injection cavity is typically very small, making bone cement injection inconvenient.

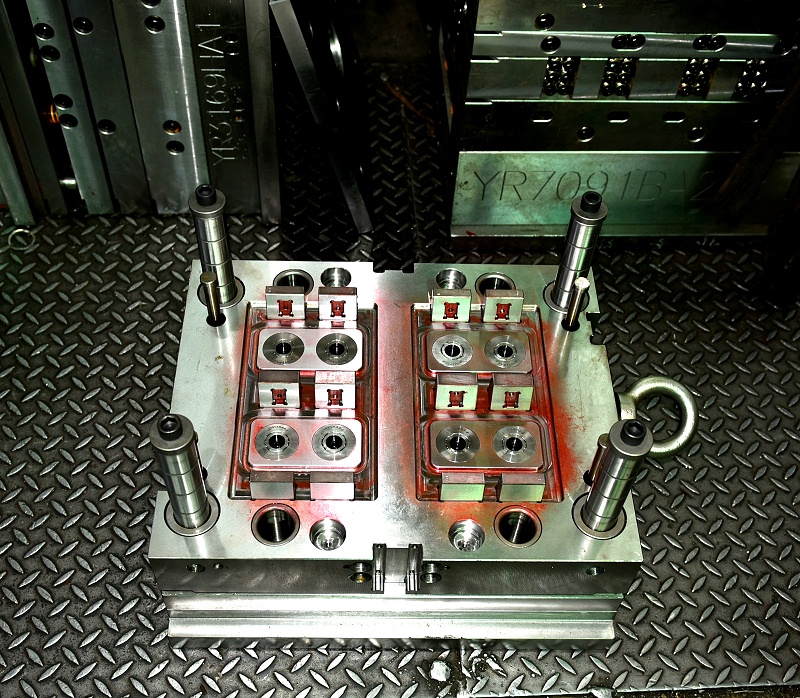

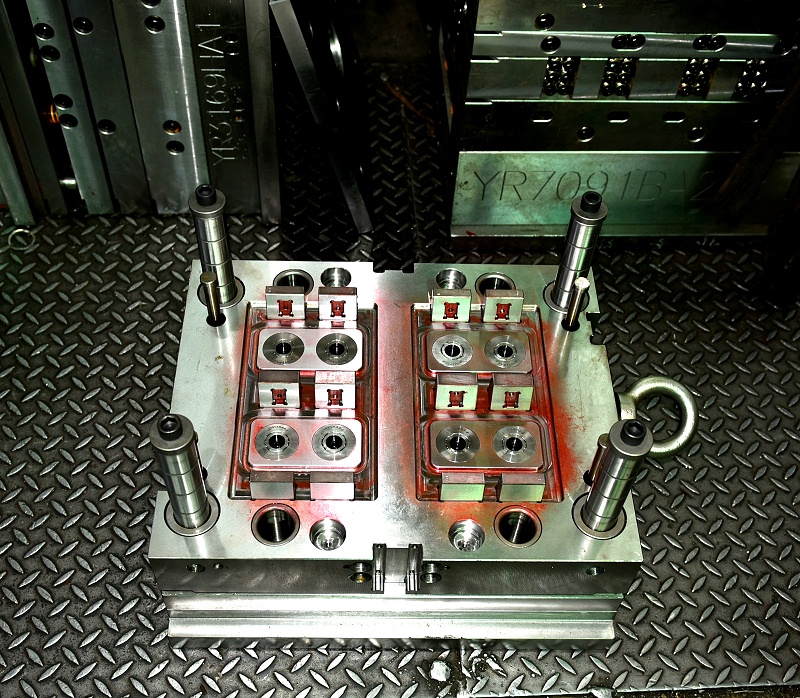

This led to product upgrades and the company, Shibang Injection Mold Processing Factory, to enhance the production of injection molded components for medical bone cement kits. We utilize a pusher head in conjunction with an injection channel to achieve a two-stage push-and-pull operation, pushing bone cement into the pre-concrete cavity and then into the body. This eliminates the need to transfer bone cement into a separate container, saving surgical time. The injection channel's cross-section is smaller than the pre-concrete cavity's, increasing the injection pressure and facilitating a smoother surgical procedure.

The bone cement syringe consists of: a premixing tube, one end of the premixing tube, and two openings connected to the premixing chamber at both ends of the premixing tube; the syringe includes an injection rod, an injection tube, an injection tube end face, an injection hole, one end of the injection rod, and the injection tube is slidably installed in the premixing tube, the shape of the injection plate matches the shape of the inner wall of the premixing chamber, the injection rod is installed in the injection channel, the injection rod passes through the injection hole, the injection head is located in the premixing chamber, and the shape of the injection head matches the shape of the inner wall of the injection channel.

3.500+ Material Choices Custom Injection Molding