Last month, a customer in Guangzhou contacted us through the HUIWEN official website regarding a system receiver (medical device housing injection molding). They provided us with 3D drawings. The dimensions and structure of this product appeared straightforward, but the actual mold creation and injection molding presented significant challenges. Furthermore, the customer desired a white pearlescent finish, a process also used on many automotive surfaces. While its advantages include a pleasant feel and bright color, its disadvantages are slow production and a high defect rate. The customer explained that they had previously approached several injection molding suppliers but could never achieve the desired results, and asked if we could manufacture this product.

After receiving the customer's drawings, I immediately organized and shared their requirements with our engineer, Mr. Huang. After reviewing the drawings, Mr. Huang immediately convened an engineering

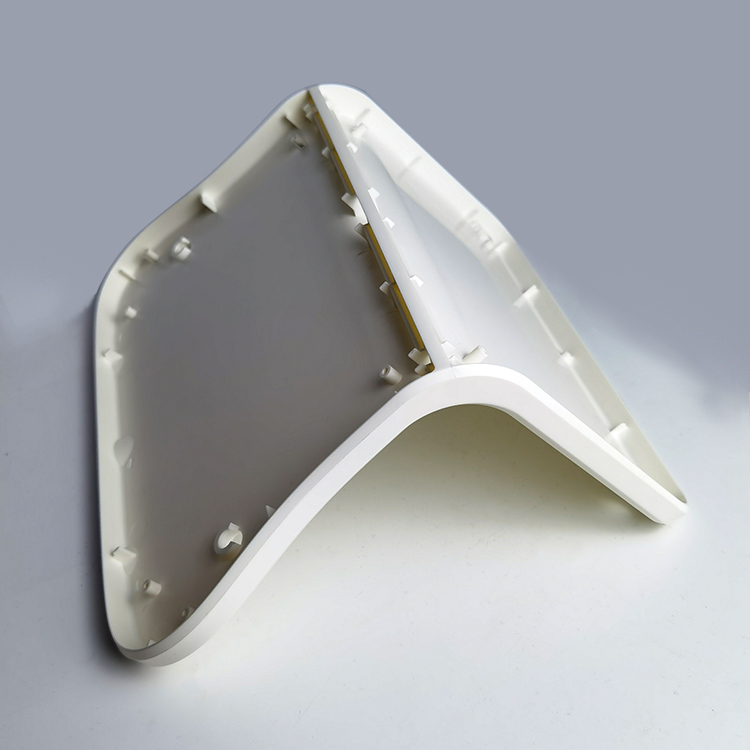

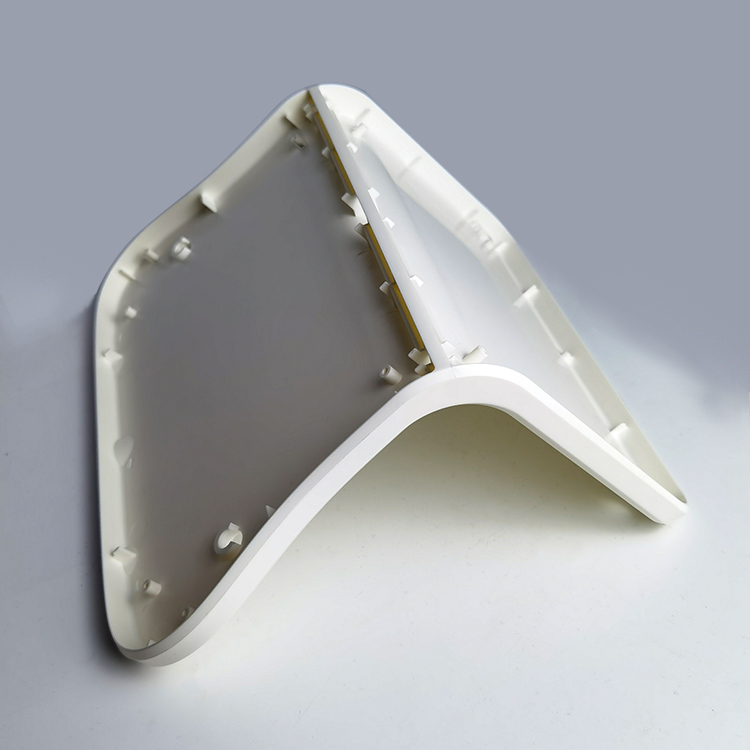

meeting to discuss the mold structure for this custom medical housing. This product consists of three injection molded parts and is relatively large. The top cover has a 90-degree corner, which undoubtedly presents a significant mold creation challenge. The placement of the screw holes on the back, the venting, the clips, and other details all needed to be confirmed with the customer.

Because this wasn't a consumable part and the customer wasn't ordering large quantities, we decided to create all three components in a single mold. This reduced the cost of two molds, allowing for one set of molds for each component. After confirming all necessary details, the mold room began making the mold. 20 days later, once the mold was complete, we began injection molding and surface treatment.

Spraying this pearlescent paint is expensive, time-consuming, and has a high defect rate, challenging the painter's skills. Many cars also use this finish, creating a glossy, reflective finish with tiny luminous particles for a more stylish look. To minimize the defect rate, our Shibang technician, with over 30 years of production experience, personally sprayed the paint and mentored the workers nearby.

After the first batch of finished products came out, everyone was very happy. After Master Huang confirmed the quality, he immediately asked me to send them to the customer. After receiving the samples, the customer was very satisfied with our quality. Our HUIWEN Plastics is not only a system receiver medical housing injection molding manufacturer, but can also customize

plastic Products for customers. From the customer's perspective, we can come up with a good solution to ensure quality and save costs. Serving customers well is our unchanging purpose.

3.500+ Material Choices Custom Injection Molding